Cold Blackening Chemical

- Cold blackening chemicals are used in metal finishing to create a black oxide coating on ferrous metals, such as steel and iron, at room temperature. This process enhances corrosion resistance, reduces glare, and provides an attractive dark finish without requiring high temperatures, as in traditional hot black oxide treatments.

* Cold Blackening Process

1. Cleaning:

- Thoroughly clean the surface to remove oils, grease, dirt, and rust.

- Use a degreaser or alkaline cleaner.

* Rinsing:

- Rinse the metal with water to remove cleaning residues.

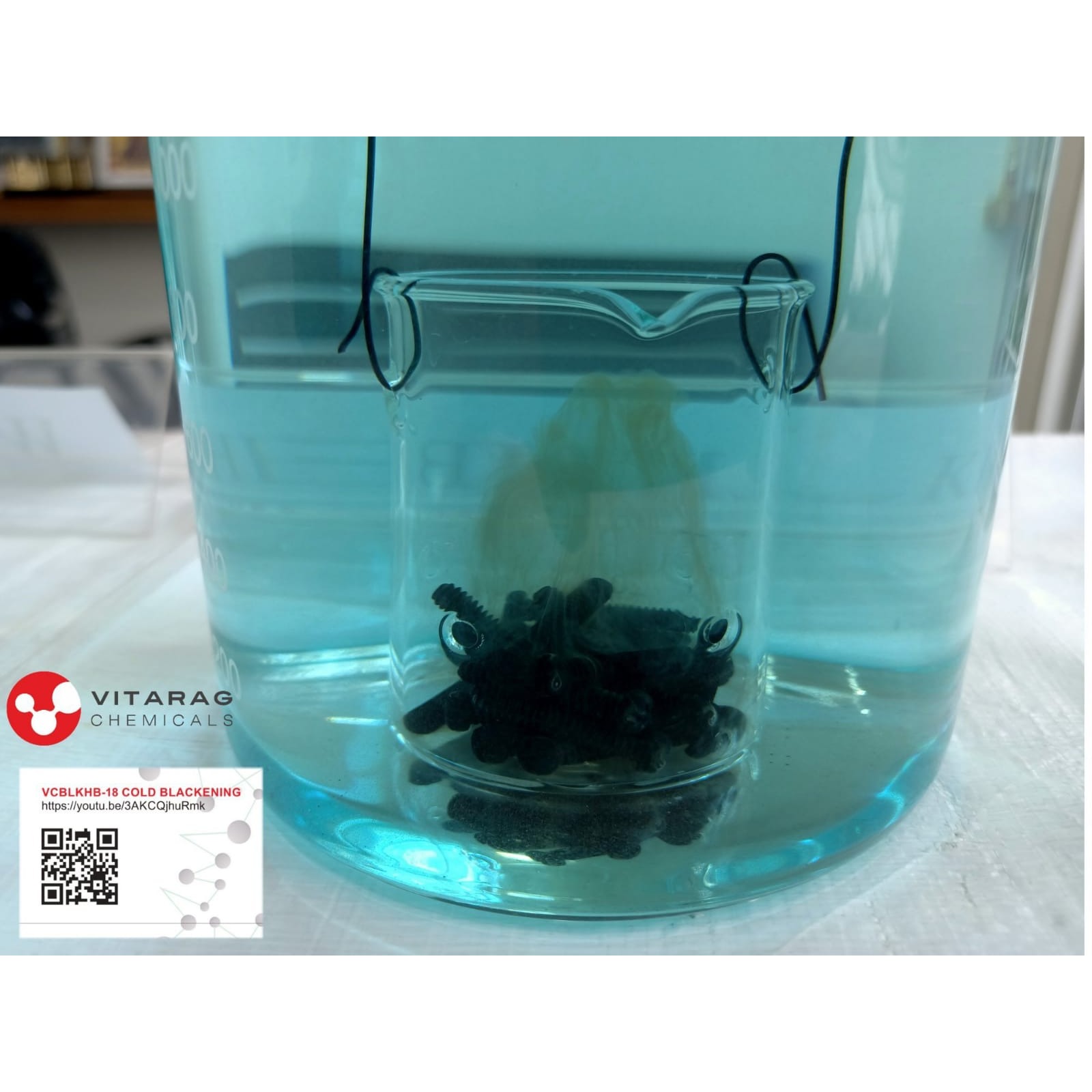

2. Cold Blackening Application:

- Submerge or apply the blackening solution to the metal.-

- This solution often contains selenium dioxide, which reacts with the surface to form a black oxide layer.

* Rinsing:

- Rinse the part again to remove excess chemical residues.

3. Sealing (Optional but Recommended):

- Seal the blackened surface with an oil-based or wax-based rust preventative for enhanced durability and corrosion resistance. # Cold Blackening Chemical Manufacturer.