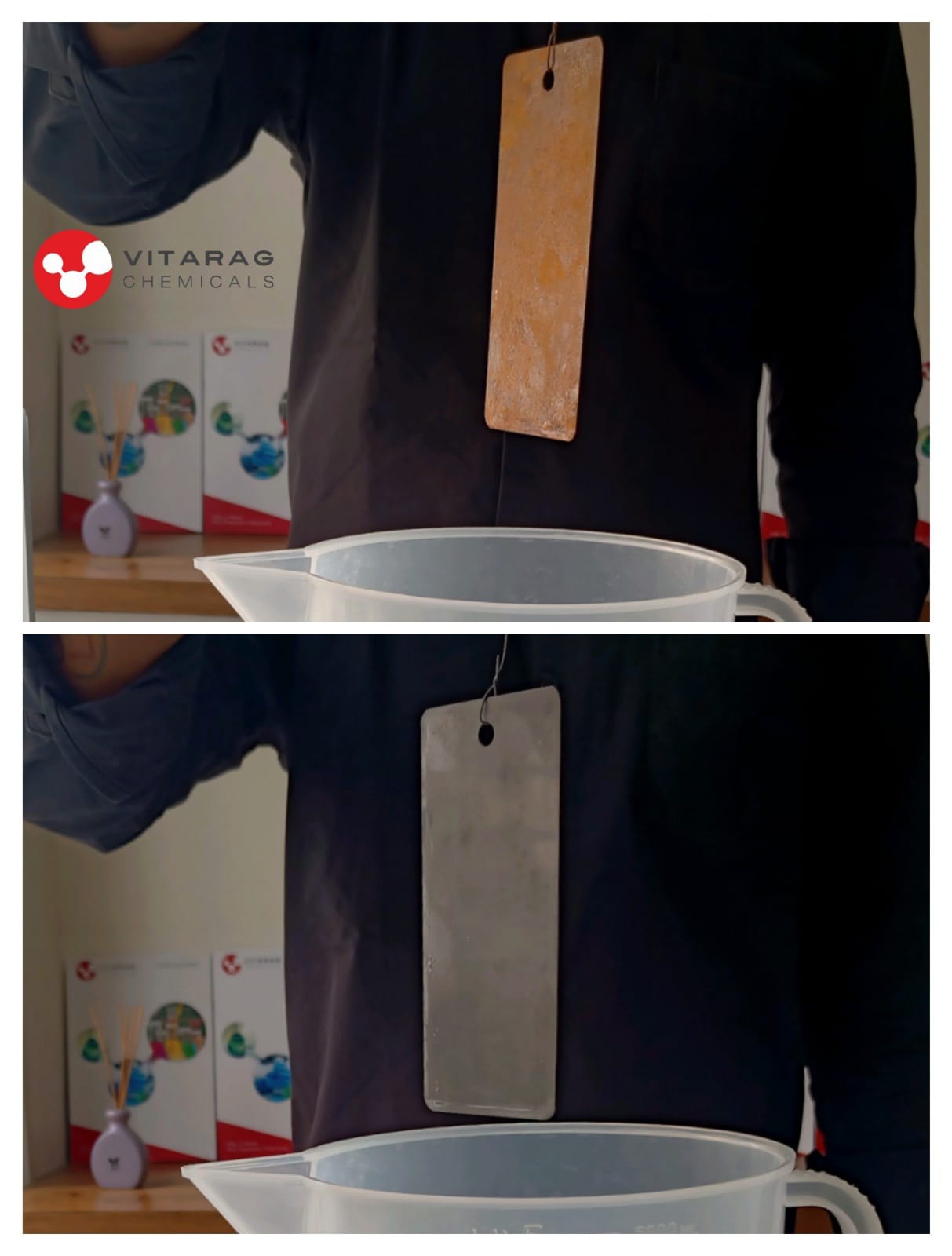

1. ZNP-54 ZINC PHOSPHATING CHEMICAL 2. Generally zinc phosphate conversion coating is used to provide long lasting corrosion protection. Almost all automotive industries use this type of conversion coating. It is suitable for the products come against hard weather conditions. Coating quality is better than iron phosphate coating. It forms 2 - 5 gr/m² coating on the metal surface when used as under paint. Application, set up and control of this process are more difficult than other methods and can be applied by immersion or spray. 3. Organic compounds like nickel and manganese are added to the bath to increase the coating performance. Also activation can be used to form small phosphate crystals on the metal surface before zinc phosphating. 4. Zinc phosphate reaction happens in amorphous shape with gray - black color. 5. pH optimizers are added to accelerate the reaction. Temperature, application time, concentration, pH, total acid and free acid values are the parameters which must be under control. 6. Zinc phosphates, coating range between 7 - 15 gr/m², are used in wire drawing, tube drawing and cold forming industries. Phosphated metal workpieces are prepared to the next stage by application of protective lubricans and soap

Send Message