Blackening service for metal parts

- Blackening, also known as black oxide coating, is a finishing process used to create a black surface on metal parts for aesthetic, corrosion resistance, and wear protection purposes. It’s widely used in industries like automotive, firearms, tools, and decorative metalwork.

- Key Aspects of Blackening Services for Metal Parts:

1. Types of Metal: Blackening can be applied to steel, stainless steel, copper, brass, and sometimes aluminum. The specific blackening process can vary depending on the metal.

1Process Overview:

- Cleaning: The parts are thoroughly cleaned to remove oils, dirt, and oxidation.

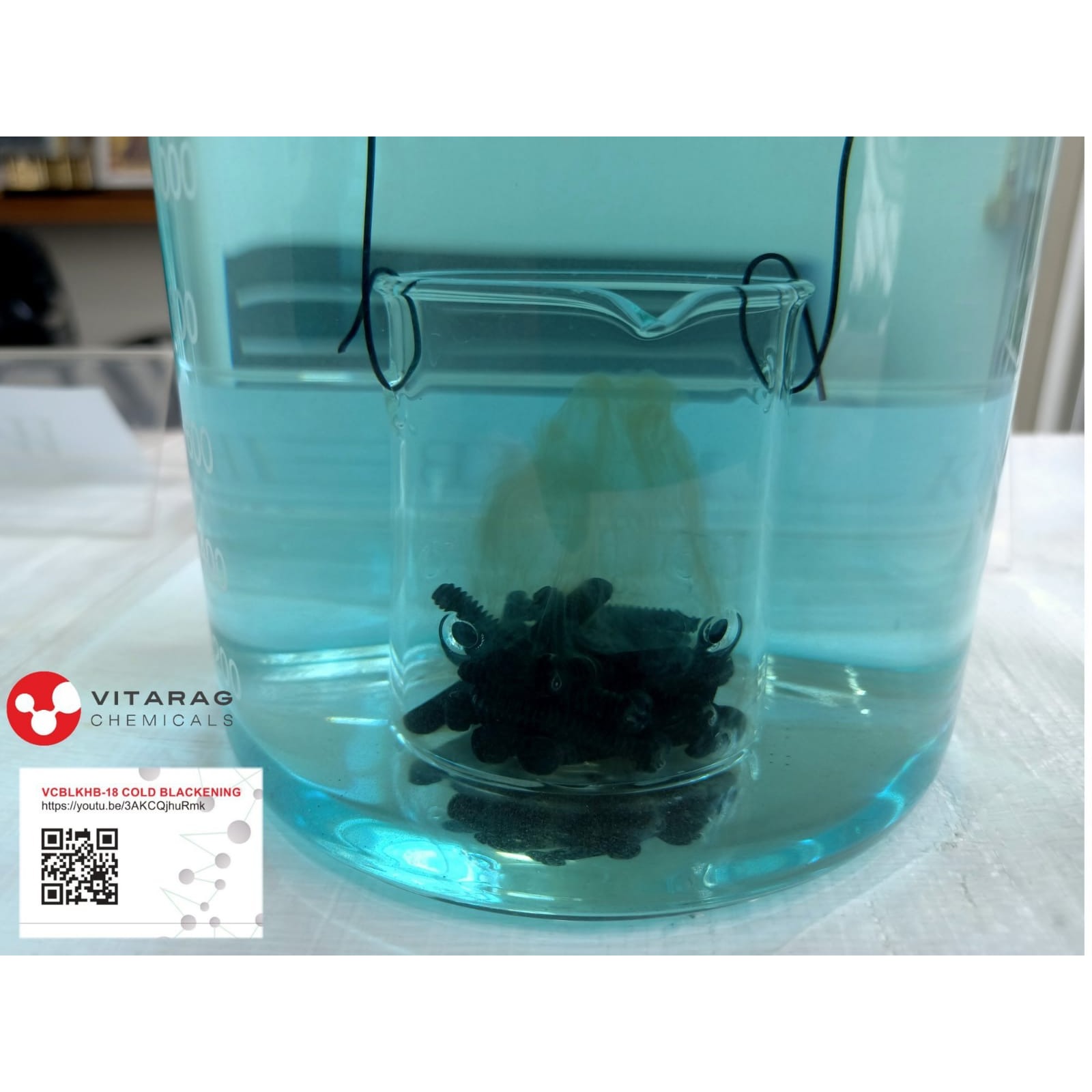

- Application of Blackening Solution: The metal parts are immersed in a black oxide solution (hot or cold) which reacts with the surface to form a protective black finish.

- Sealing: After blackening, parts are often dipped in oil or wax to seal the surface and provide additional corrosion protection.

Keywords

1. Types

metal parts

Key Aspects

black surface

stainless steel

1Process Overview

finishing process

Blackening service

Blackening Solution

black oxide coating

decorative metalwork

corrosion resistance

black oxide solution

protective black finish

wear protection purposes

specific blackening process

additional corrosion protection