7 TANK PROCESS CHEMICAL MANUFACTURER

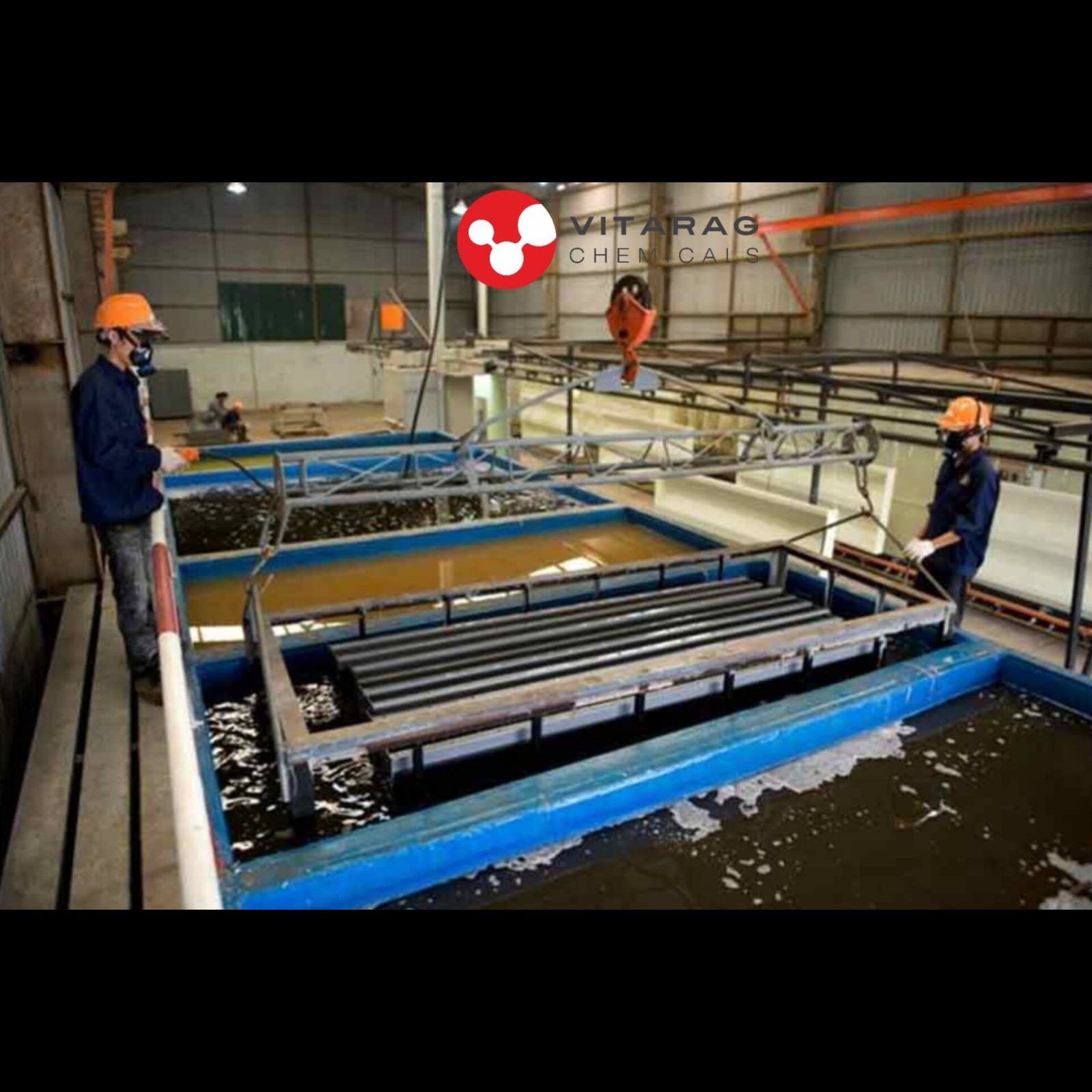

- A '7 Tank Process' is commonly used in metal surface treatment, particularly for pretreatment before powder coating or painting. It ensures proper cleaning, degreasing, and coating adhesion, as well as corrosion resistance. If you're looking for chemical manufacturers that provide chemicals for the 7-tank process, here’s how we can break it down:

* Common 7 Tank Process Steps

1. Degreasing (Alkaline Cleaner)

1. Water Rinse 1

3. Derusting/Descaling (Acid Pickling)

4. Water Rinse 2

5. Activation

6. Phosphating (Zinc/Iron Phosphate)

7. Passivation / Final Rinse (with DM Water or Chrome/Non-Chrome Seal). # 7 TANK PROCESS CHEMICAL MANUFACTURER.