Blackening Agents For Metal

- Blackening agents for metal are chemicals used to create a black oxide or blackened finish on metal surfaces. This process enhances corrosion resistance, reduces light reflection, and improves aesthetics. Here are some common blackening methods:

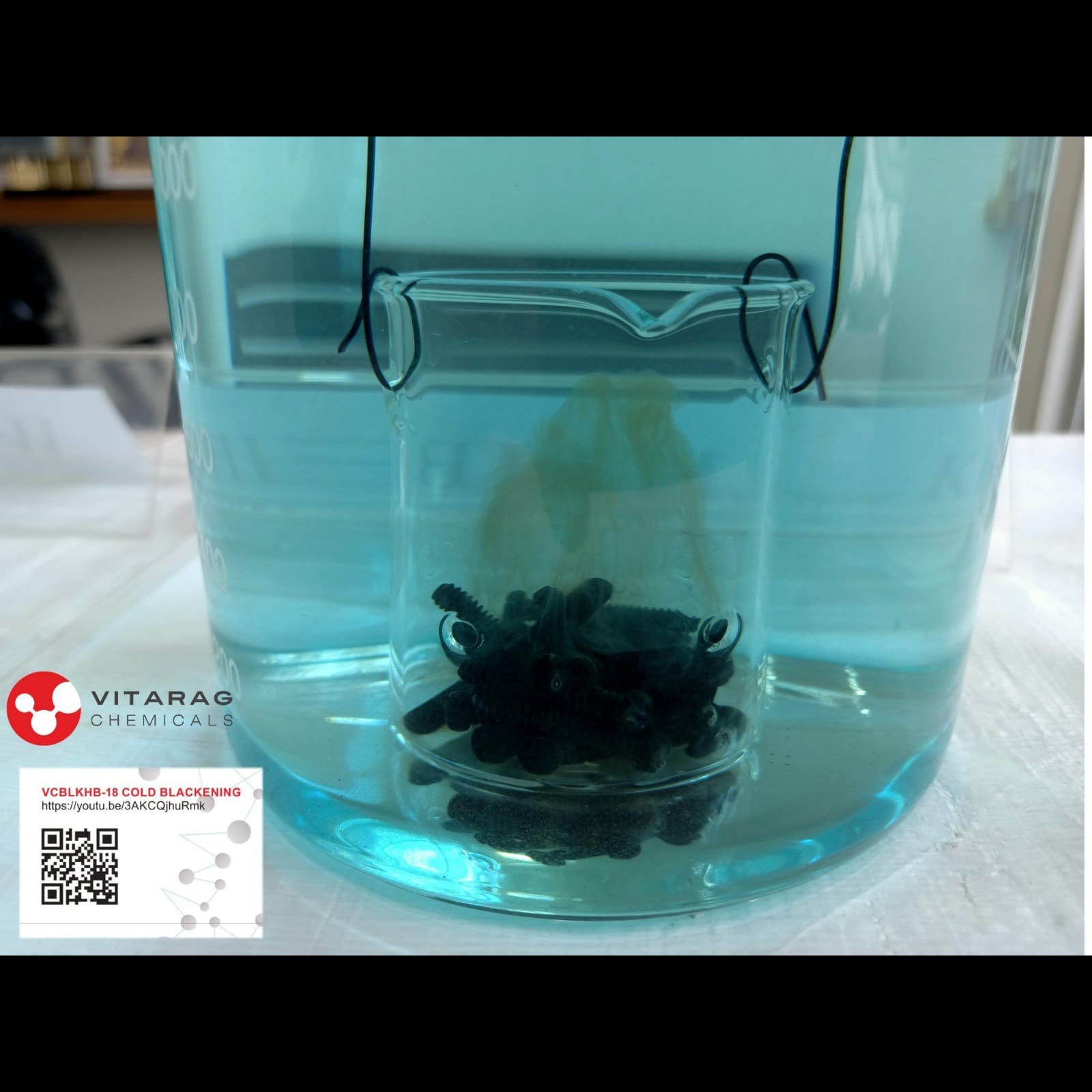

1. Cold Blackening (Room Temperature)

Chemicals Used: Copper selenide, selenium dioxide

Metals: Steel, iron, stainless steel, aluminum, brass

Process: Chemical immersion at room temperature

Pros: Quick, easy to apply, minimal heating required

Cons: Less durable than hot black oxide, requires sealing with oil or wax

2. Hot Black Oxide (High Temperature)

Chemicals Used: Sodium hydroxide, nitrates, nitrites

Metals: Steel, stainless steel, cast iron

Process: Immersion in a heated (285°F / 140°C) alkaline bath

Pros: Highly durable, excellent corrosion resistance (when sealed with oil)

Cons: Requires strict temperature control and safety precautions. # Blackening Chemical Manufacturer.