VCBLK HB-18 cold blackening chemical

- Cold blackening is a chemical process used to create a black oxide coating on ferrous metals (steel, iron, and some stainless steels) at room temperature. It enhances corrosion resistance, reduces light reflection, and improves aesthetics without significant dimensional changes.

* Cold Blackening Chemicals & Process

- Cold blackening chemicals typically contain copper selenide or other reactive compounds that chemically convert the surface of the metal into a dark, protective layer. Unlike hot black oxide, this process does not require heating.

# Key Steps in Cold Blackening

- Cleaning & Degreasing – Removes oils and contaminants.

- Surface Activation – Prepares the metal for uniform reaction.

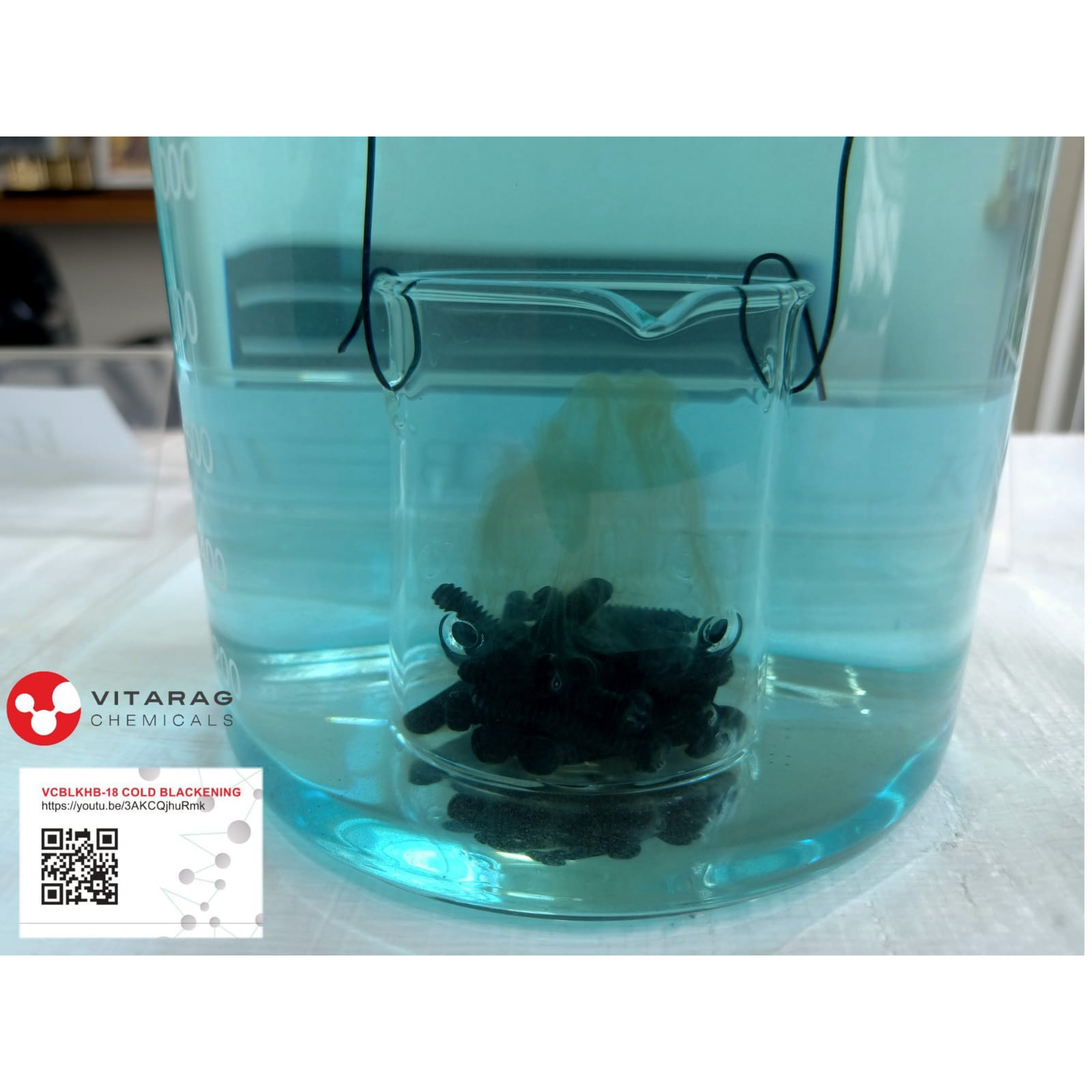

- Cold Blackening Bath – A chemical immersion process that forms a dark conversion coating.

- Rinsing – Removes excess chemicals.

- Sealing (Oil or Wax Coating) – Enhances corrosion resistance and provides a smooth finish # VCBLK HB-18 cold blackening chemical # VCBLK HB-18 cold blackening chemical