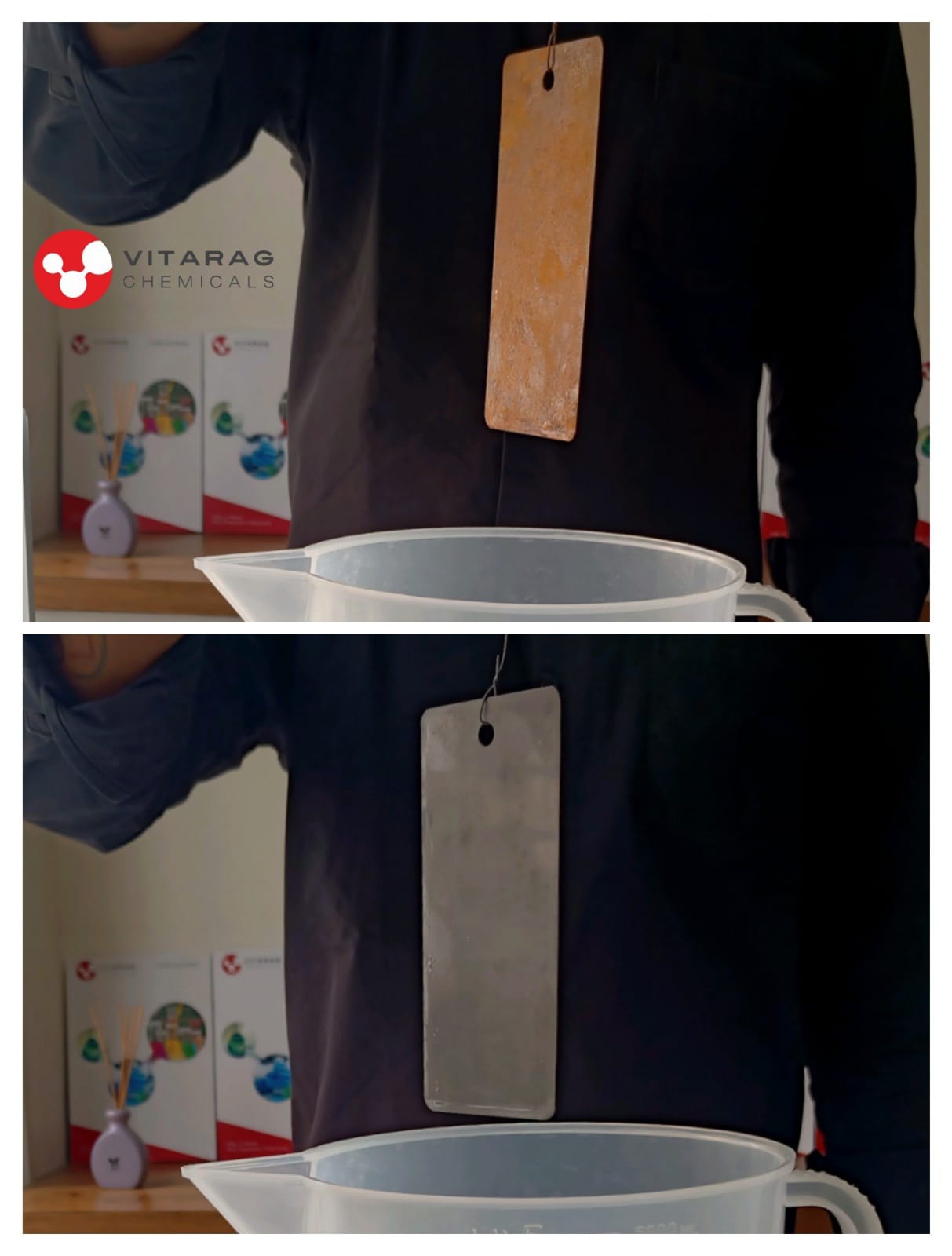

VCHEMKLIN is designed to simplify pre-paint treatment of metal aircraft surfaces like wing sections, fuselages as well as automobiles and tractor assemblies. Complete assembled planes can be cleaned and conditioned right on the field without the use of special equipment. Easy hand application of VCHEMKLIN by brushing, swabbing or spraying provides thoroughly clean passivated surface ready for touch-up or complete refinishing. FAST, LOW COST METHOD :- Passivating with VCHEMKLIN is not intended to replace anodizing and chromatising in aircraft and automobile manufacturing. However it produces similar results faster and at much lower cost where those processes are impractical or unavailable. REMOVES, PREVENTS CORROSION :- Light oxides and surface corrosive residues are quickly and easily removed by merely applying VCHEMKLIN by wipe method and rinsing with water. Surfaces is made chemically inert oxide and soil free to prevent corrosion from spreading under paint coatings.

Send Message