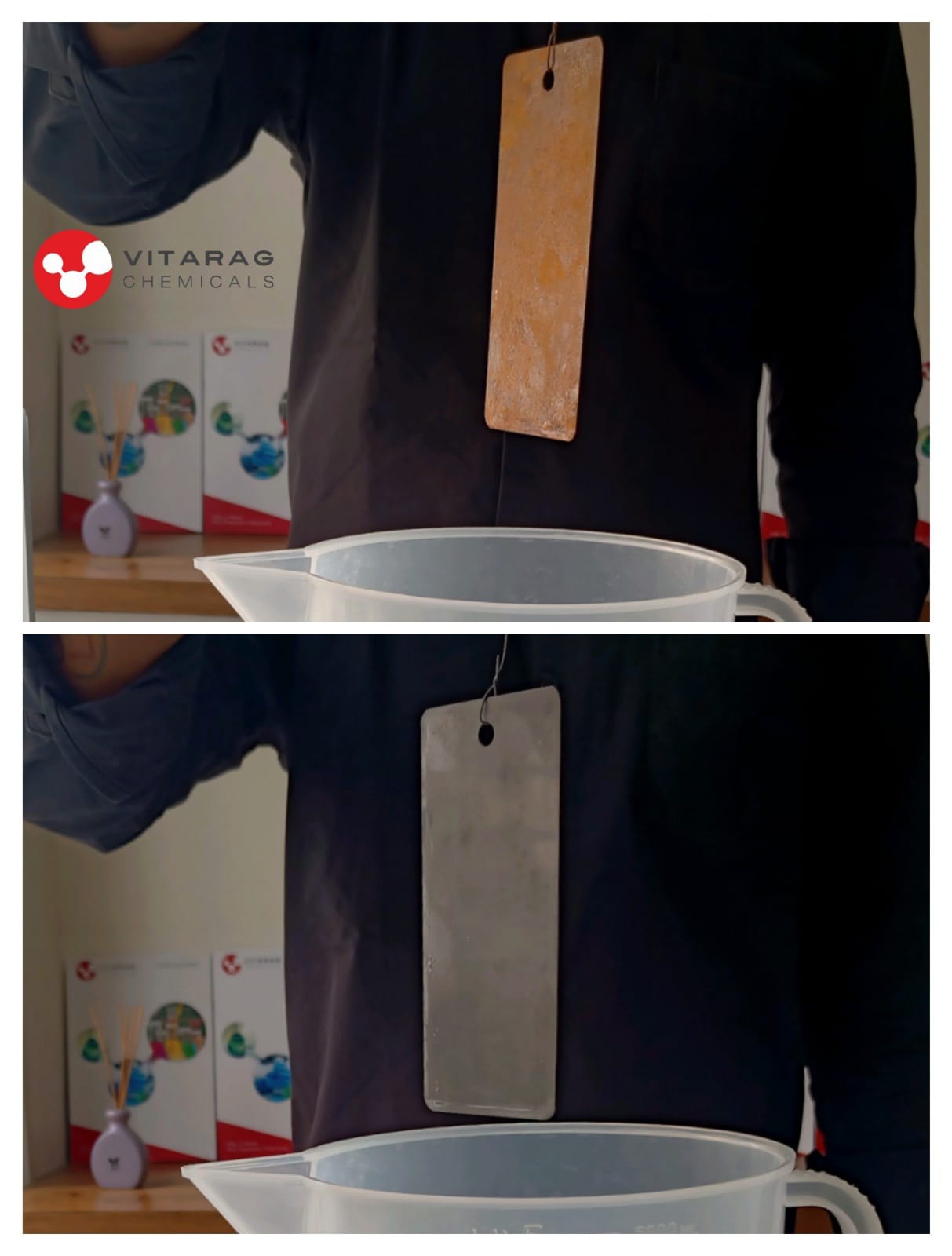

8-Tank Process Chemicals for Powder-Coating : A Comprehensive GuideDiscover the top-quality chemicals from Vitarag Chemicals for the 8-tank process. Our specially made formulas are perfect for modern industries, giving you great performance and reliability. Improve your work with our latest products, made by experts with lots of experience. When you’re powder coating, it’s very much necessary to use good chemicals for a perfect finish.Vitarag Chemicals has the right products for each step of the powder coating process. Start with our cleaners, which remove dirt and grease from metal surfaces. They also help you in making them ready for painting. Then use our special phosphating chemicals to protect the metal from rust and help the paint stick better. With Vitarag Chemicals, you get top-notch quality and expertise. Our chemicals make the powder coating process superior, giving you professional-looking finishes that meet all the standards. Each chemical in the eight-tank process is important, helping you get great results every time.

Send Message