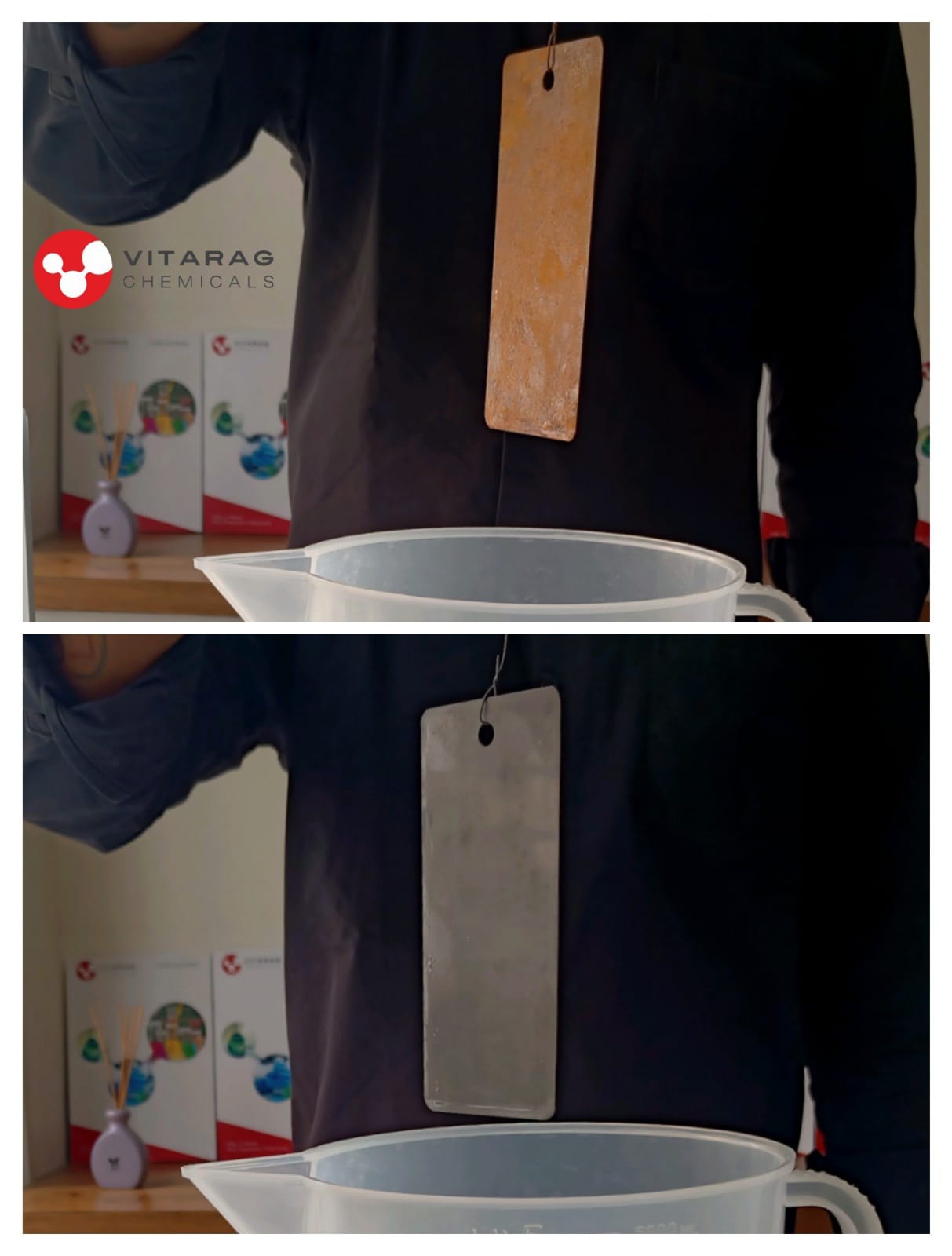

INTRODUCTION : CORONIL-555 is an antirust chemical compound that is readily soluble in water. It is widely used to give temporary protection against rusting of steel tubes, pipes, strips, profiles and various other ferrous parts, during process. CORONIL-555 is an antirust chemical compound that is readily soluble in water. USES : 1) It can be used as an anti-rust treatment after acid pickling or phosphating. The acid pickled or phosphated parts after rinsing are dipped or sprayed with the solution of CORONIL-555. 2) It can be used as a Passivation cum Neutralizer for machined components, for multi-metal assemblies, for ground parts and for various maintenance jobs after cleaning. It can be used either by dip, spray or by circulation. 3) It can be used as an antirust additive for : (a) Air-testing in water. (b) Hydro testing (especially of pipelines). 4) It can be added to cutting coolants or machining fluids to prevent rusting of cutting tools and workpieces for a few days.

Send Message